Elevating Sustainability With Velox’s

Direct-To-Shape Digital Can Decoration Technology

Imagine a world with less plastic waste and more sustainable packaging solutions. Velox is making that vision a reality.

Printing Directly On Necked Beverage Cans

Velox digital decoration solutions for printing directly on necked beverage cans offer major sustainability enhancements, reducing environmental footprint across the entire decoration process and beyond.

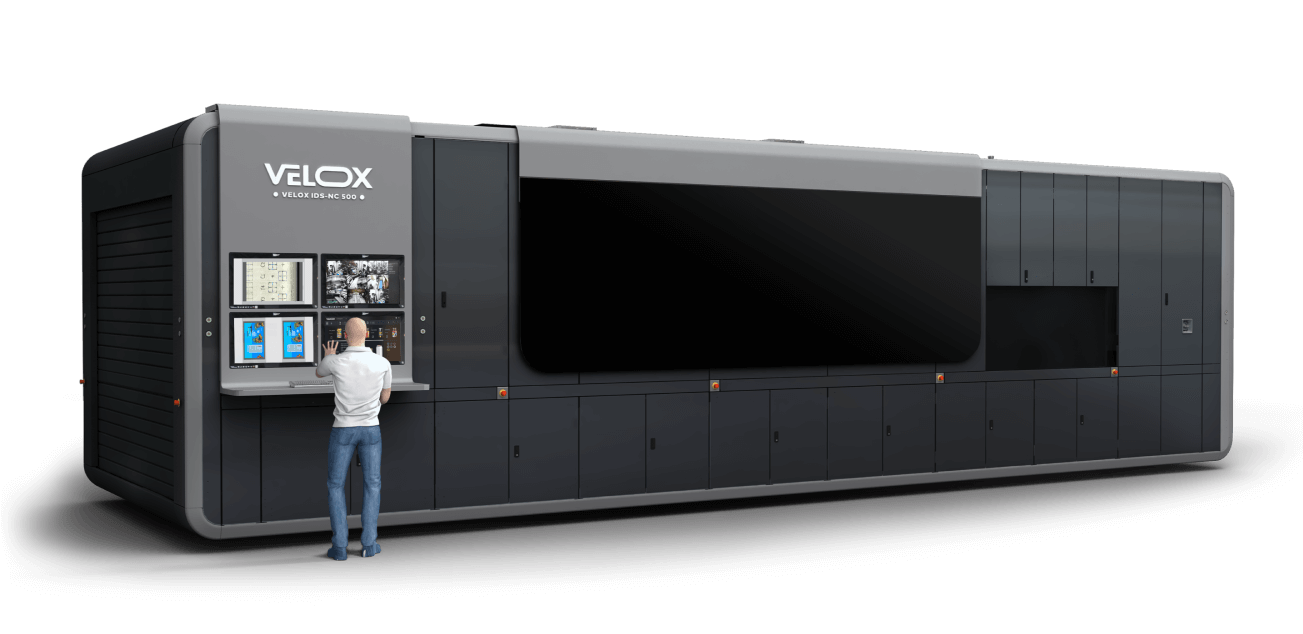

Mass Production Solutions

Our mass production solutions eliminate the use of shrink sleeves and labels, saving tons of plastics annually, while also dramatically cutting production waste.

Velox solutions make it possible to recycle the decorated cans and to reduce decoration equipment, process steps and energy consumption.

Why Switch To Velox?

Eliminating the Use of Shrink Sleeves and Labels

Replace tons of single-use plastics with direct printing

Full Recyclability

Embrace the recyclability of directly printed cans, and make your products eco-friendly

Minimizing Production Waste

Minimize overproduction, cut down storage costs, and enjoy fast printing speeds of up to 500 containers a minute

Reducing Material and Energy Consumption

Streamline Operations for Just-in-Time Production

Learn how direct-to-shape digital printing can transform your can production

200 tons of shrink-sleeve or

label plastic are saved

Eliminating The Use Of Shrink Sleeves And Labels

By replacing shrink sleeves or labels with direct printing in high-volume production, we can save tons of single-use plastics every year.

Velox's mass production direct-to-shape digital decoration technology eliminates label liners and adhesives, reducing plastic even more.

Reduced Waste And Increased Recyclability

Eliminating the need for plastic shrink sleeves and labels dramatically cuts production scrap from typical sleeving imperfections such as seam distortion, “flowering”, wrinkling, the “wet T-shirt” effect, along with machine setup.

Unlike cans decorated using shrink sleeves or labels that are not separated from the aluminum can post-use, beverage cans decorated using direct printing can also be fully recycled, making them a more sustainable and eco-friendly choice.

Less Overproduction, Shipping

And Inventory

With Velox's direct-to-shape digital decoration technology extremely high speed and short setup, producers can move to print on demand, reducing beverage can overproduction as well as inventory storage and shipping.

Craft breweries and other small-to-medium beverage brands can enjoy the inherent operational flexibility of digital technology, which offers any size runs at mass production speeds of up to 500 containers per minute.

Energy-Saving Technology

When using sleeves and labels, storage alone creates challenging environmental issues, requiring the use of climate-controlled rooms and increasing energy consumption. On top of that, shrink sleeve application to beverage can necks requires high-energy hot-air tunnels, requiring even higher energy use

In contrast, the direct-to-shape digital process requires less equipment throughout the decoration process, resulting in lower overall energy consumption.