Current Market Segments

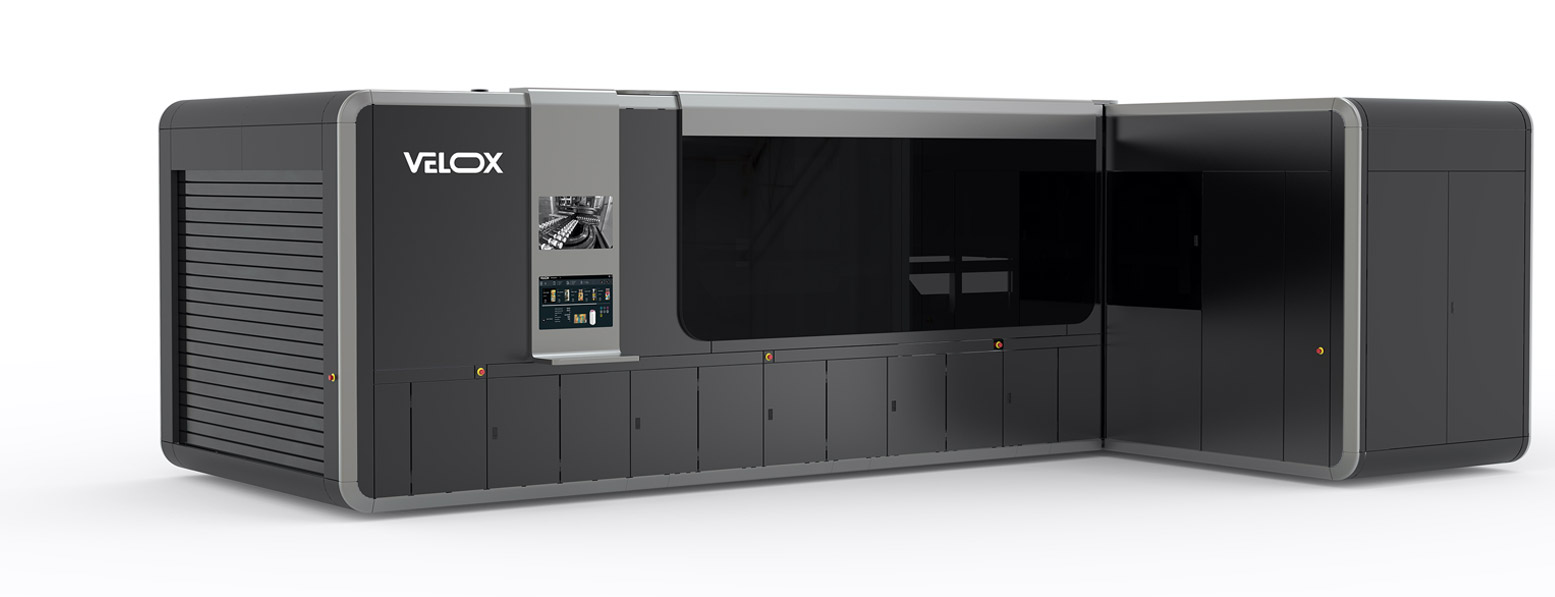

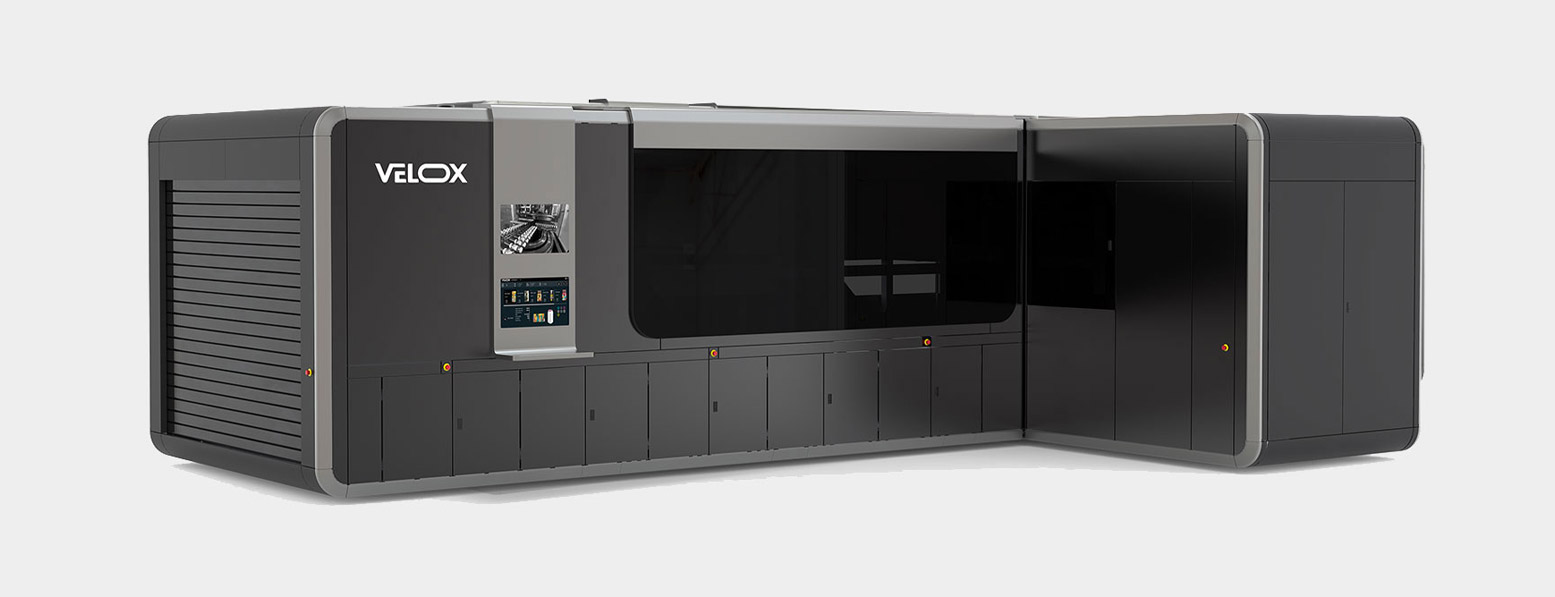

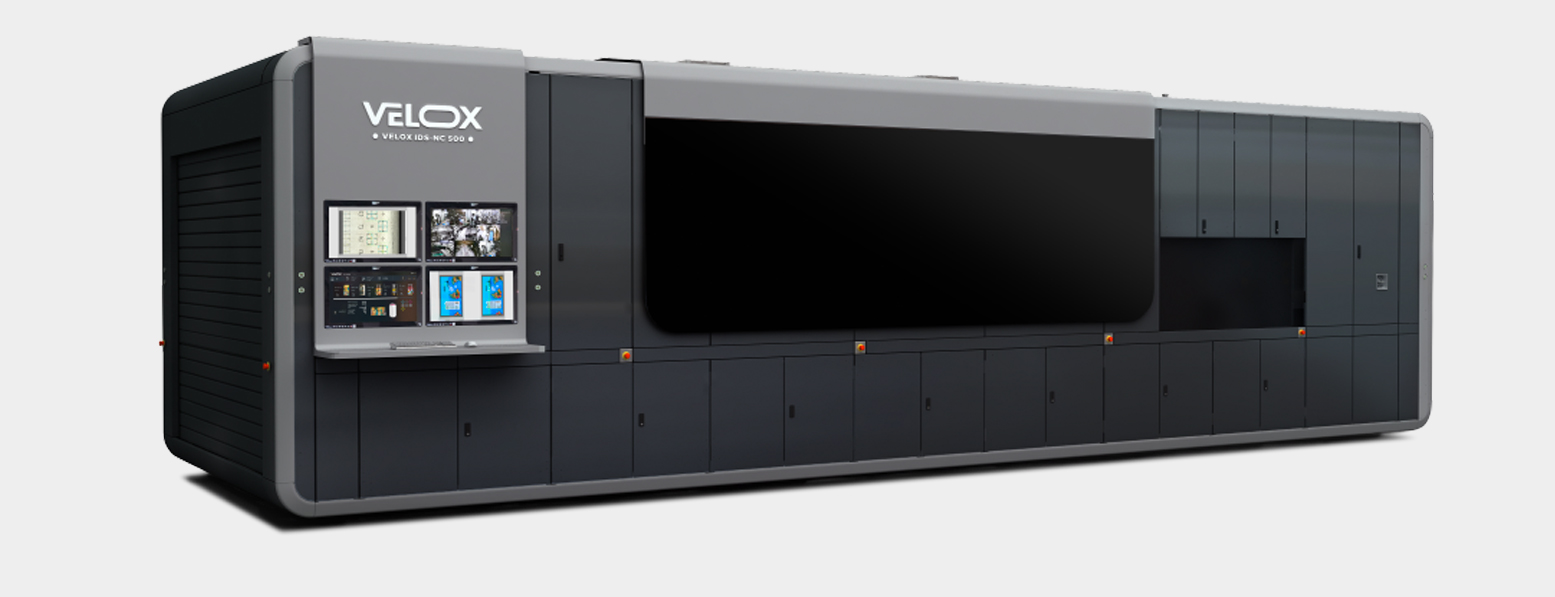

The Velox IDS family is ideal for the decoration of tubes, aerosols, dispensers

and cartridges made of plastic, aluminum and other materials.

Aluminum tubes

Learn more

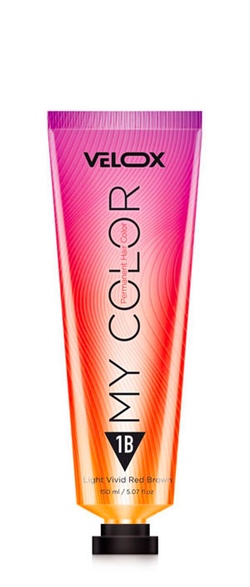

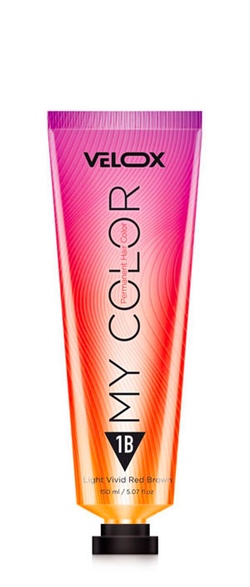

Plastic tubes

Learn more

Laminated tubes

Learn more

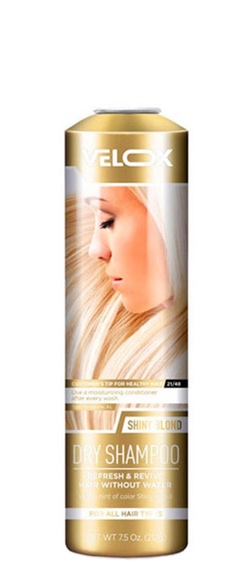

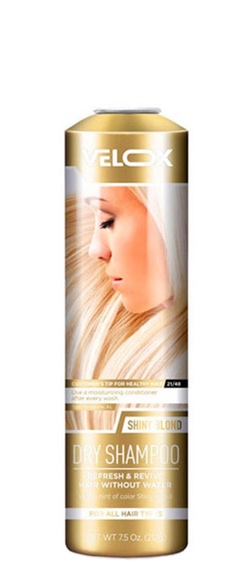

Aerosols cans

Learn more

Silicone cartridges

Learn more

Beverage Cans

Learn more

Additional Applicable Market Segments

To meet expanding market demand, Velox is continuously incorporating our

technology into machines for additional market segments to enable mass-production,

direct-to-shape digital decoration of other types of containers

Plastic bottles

Glass bottles

Aluminum bottles

3p aerosols

Aluminum closures

Glass jars

Plastic jars

Professional Services

Velox offers a comprehensive range of professional services to ensure customers’ satisfaction and success.

Our goal is to help customers maximize the extensive benefits made possible by the Velox digital solution. As such, the Velox professional services umbrella spans from solution concept development through daily operation of the line, to future developments, optimization, and ongoing improvements.

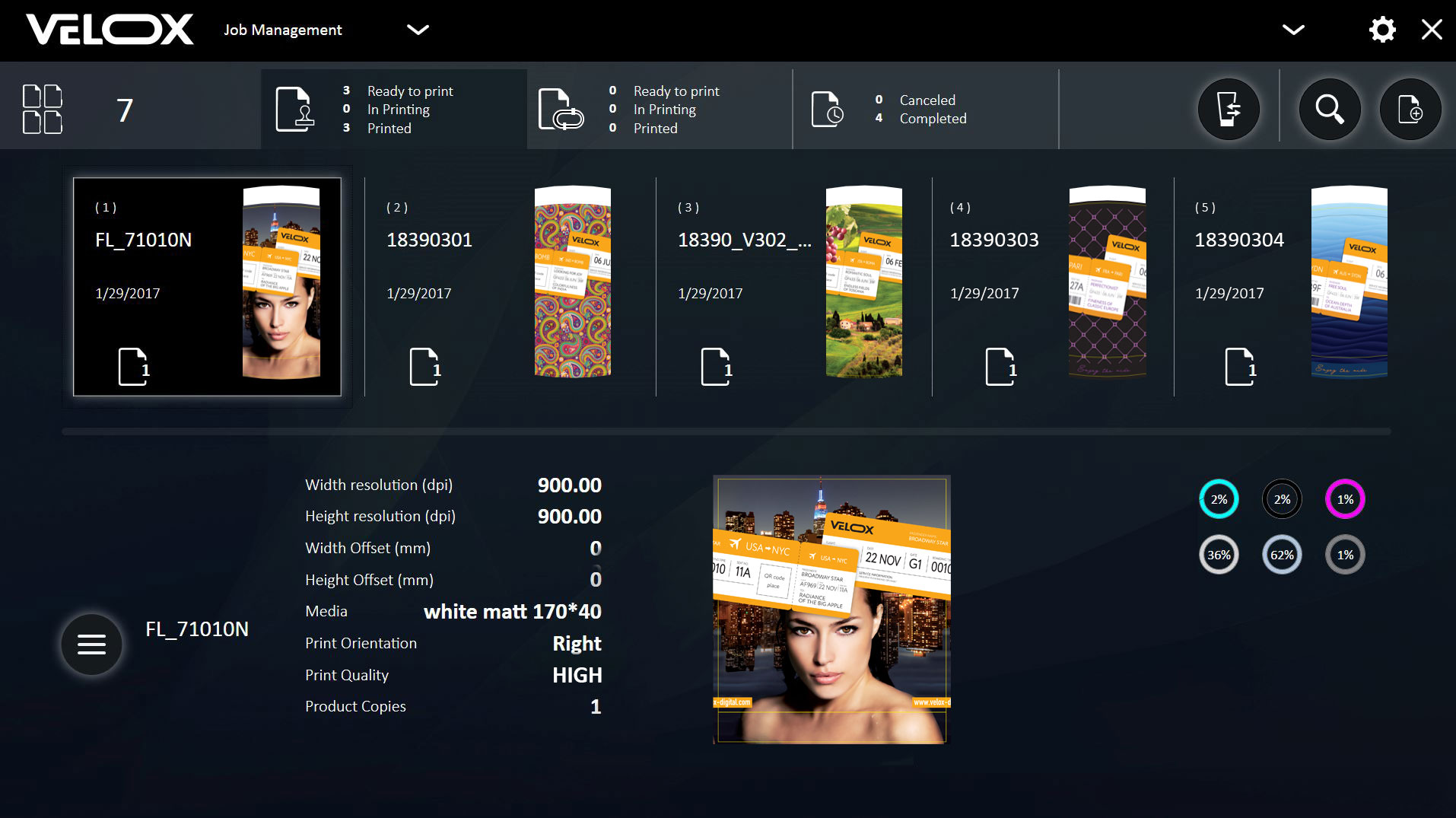

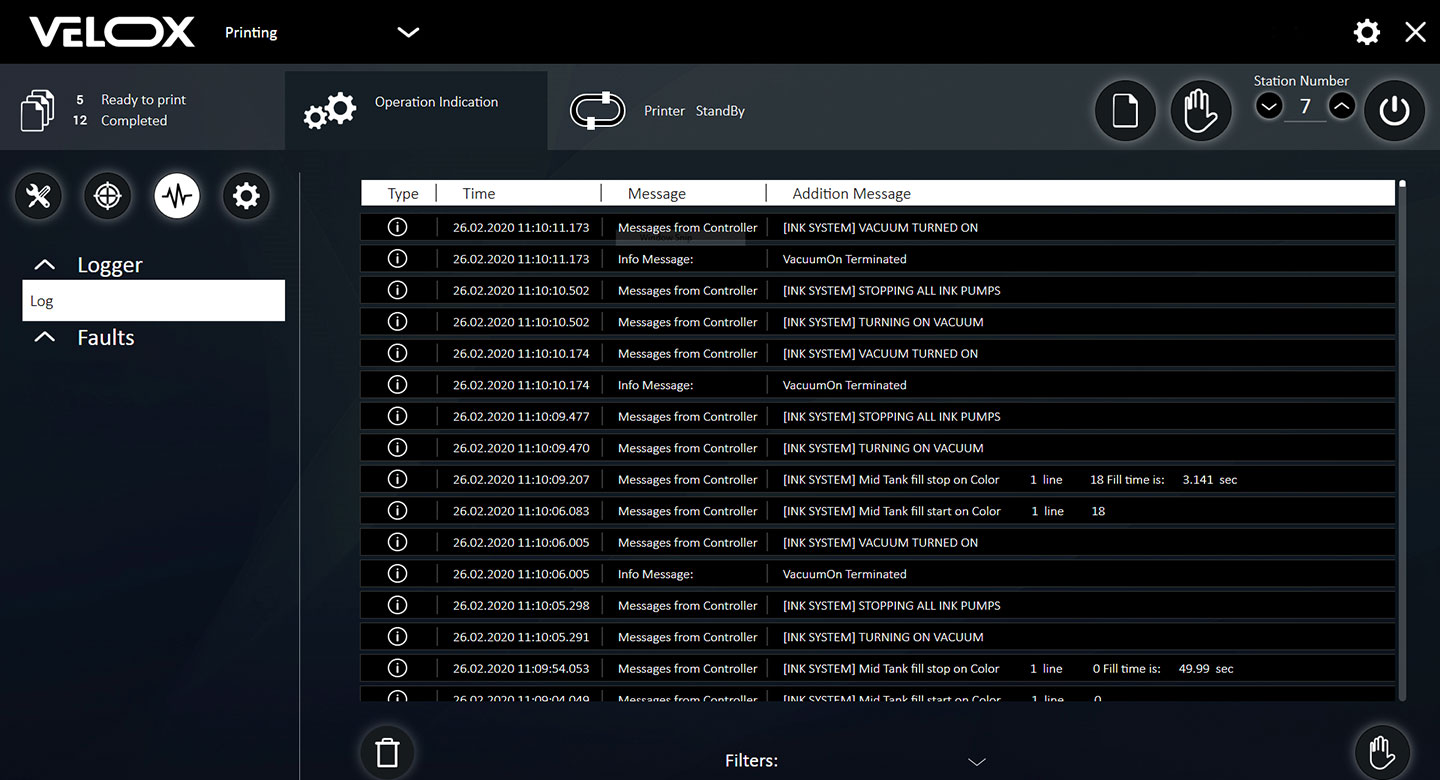

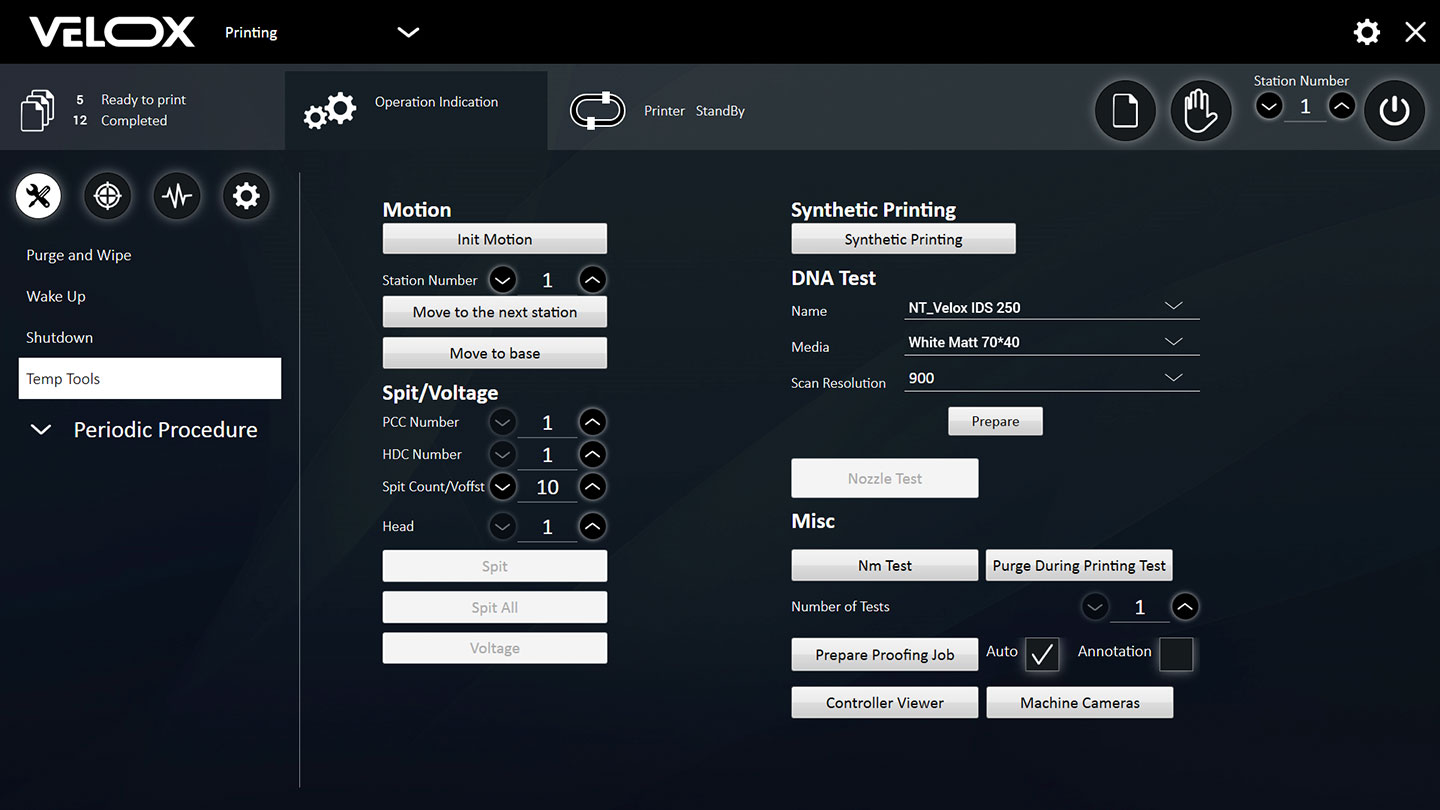

Multi-tier technical support

Production monitoring and optimization

System operation outsourcing

On-demand ink color

Velox for Designers

Joint cooperation and development with brands

Aluminum closures

Aluminum closures