- Technology

- Solutions

- Company

- Applications

- News Center

- Contact

- Careers

- Customers Login

Applicable Containers

Get all updates directly to your mailbox

The Velox IDS family is the next generation of industrial decoration systems. Based on its dual-pillar technology of system architecture and inks, coupled with first-class technical support, it delivers superior quality, high speed, and low total cost of ownership (TCO), while improving the sustainability of packaging decoration.

Direct-to-shape digital decoration solution for high-volume production of straight wall beverage cans at up to 500 containers per minute.

Mass production direct-to-shape digital decoration solution for necked beverage cans at up to 500 containers per minute.

Direct-to-shape digital decoration solution for the mass production of plastic tubes at up to 250 containers per minute.

Direct-to-shape digital decoration solutions for the mass production of straight-wall and shaped aerosol cans.

The Velox IDS family is ideal for the decoration of tubes, aerosols, dispensers

and cartridges made of plastic, aluminum and other materials.

To meet expanding market demand, Velox is continuously incorporating our

technology into machines for additional market segments to enable mass-production,

direct-to-shape digital decoration of other types of containers

Aluminum closures

Aluminum closures

Velox offers a comprehensive range of professional services to ensure customers’ satisfaction and success.

Our goal is to help customers maximize the extensive benefits made possible by the Velox digital solution. As such, the Velox professional services umbrella spans from solution concept development through daily operation of the line, to future developments, optimization, and ongoing improvements.

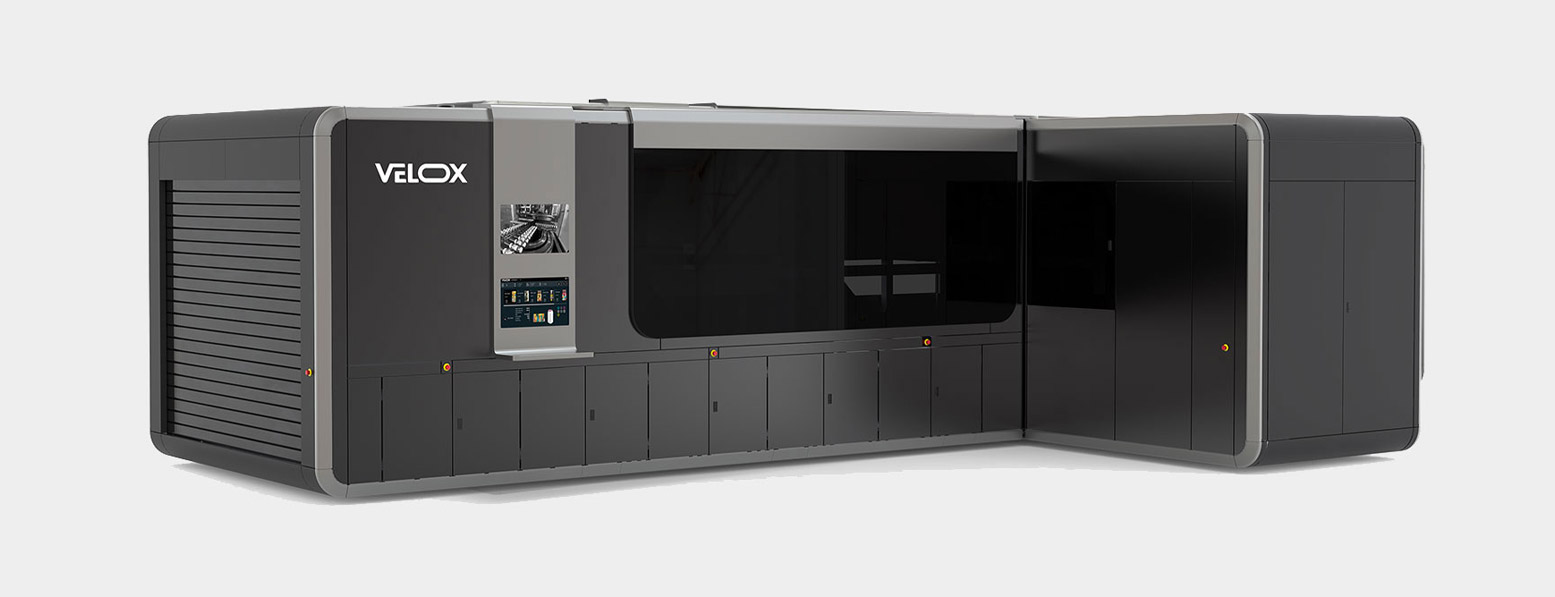

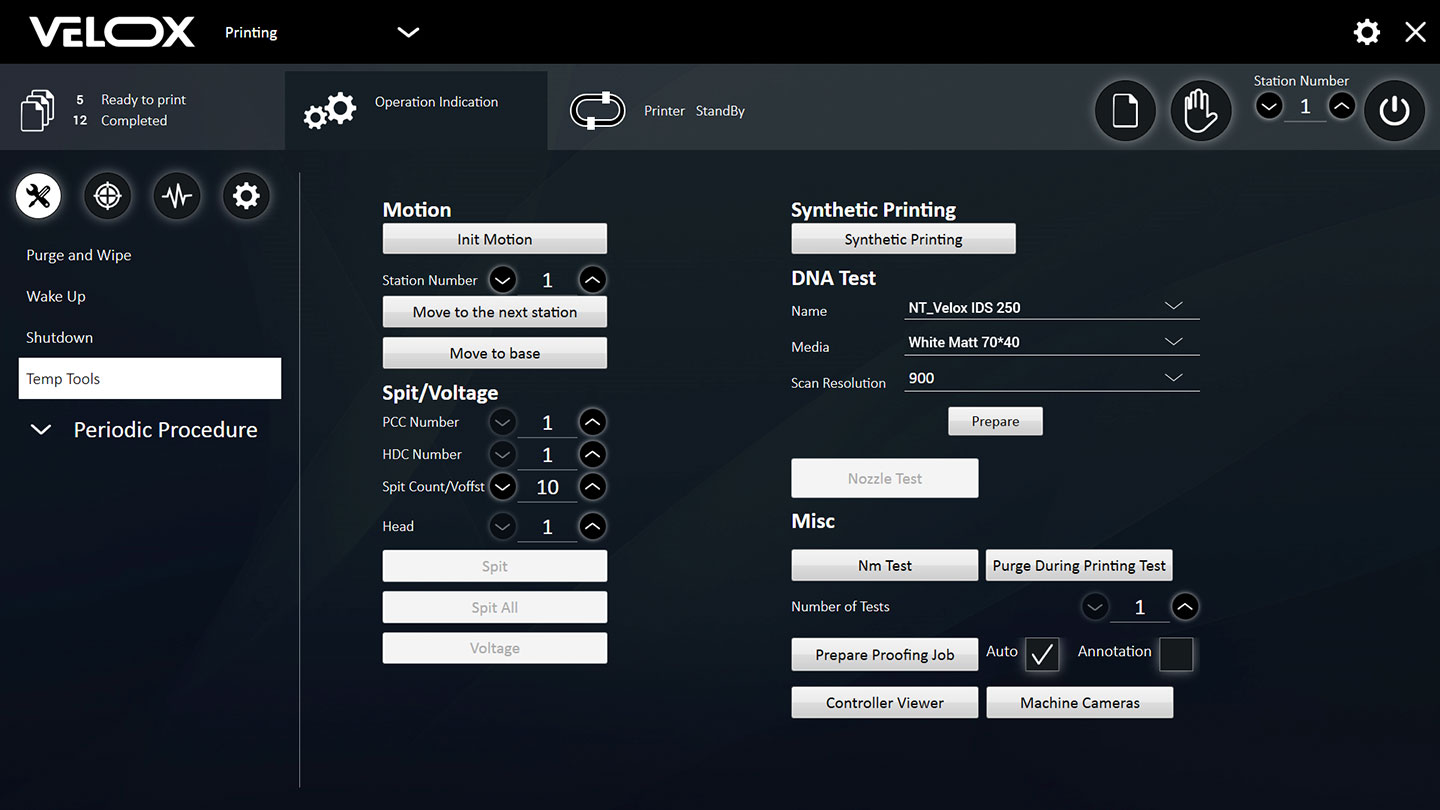

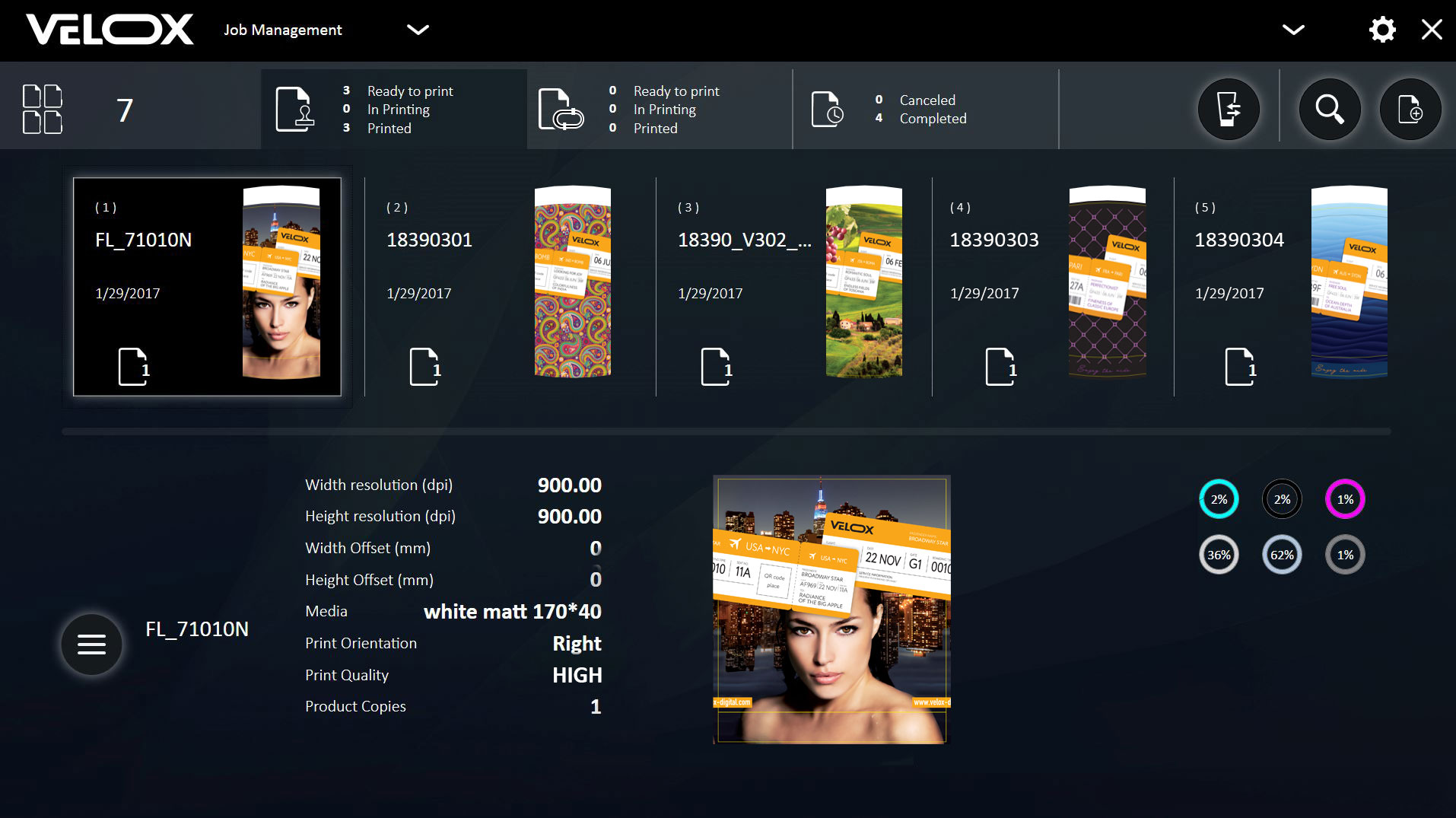

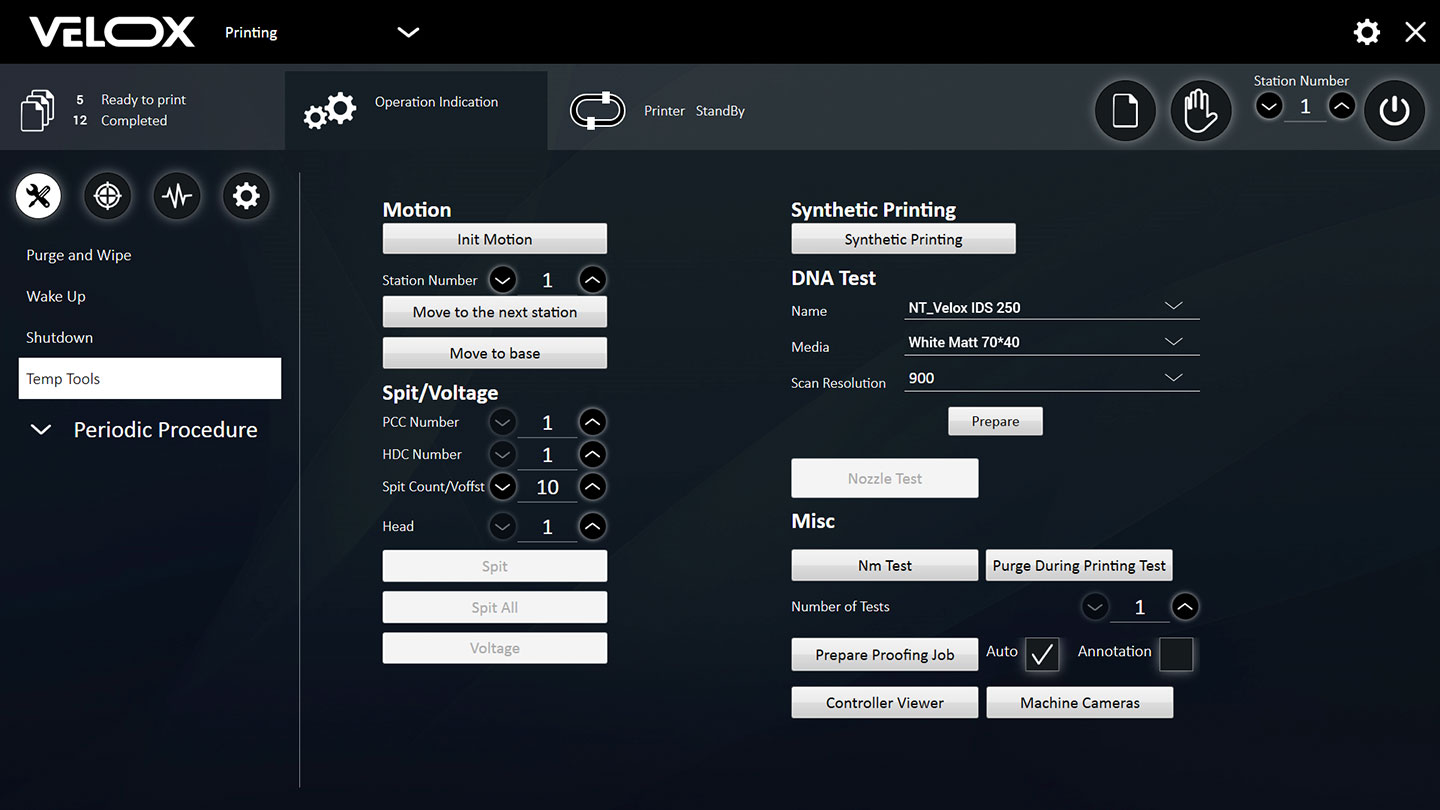

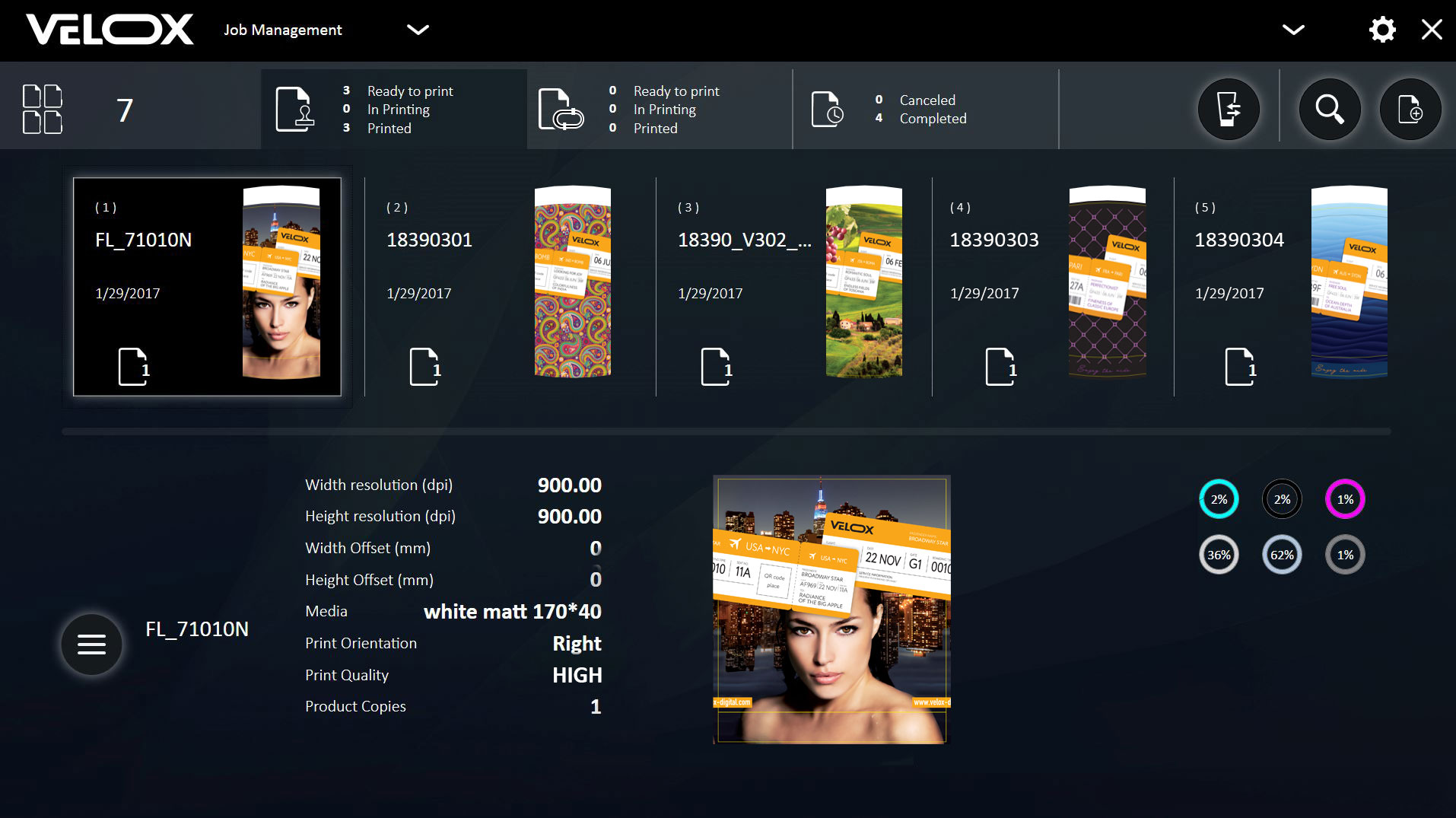

The Velox IDS 250 is a high-speed, industrial-grade direct-to-shape digital decoration solution, suited to a wide range of rigid packaging containers. It enables converters and fillers to gain a strategic leadership position and compelling competitive edge in their markets.

The Velox IDS 250 offers three sets of benefits:

Unprecedented decoration quality and capabilities

Prints any decoration profile and a unique set of decoration enhancements

Full production speed

Decorates in high quality at a speed of up to 250 containers per minute regardless of container size

Low total cost of ownership (TCO)

Combination of high production speed and high ink efficiency makes the Velox IDS 250 a principal decoration technology for the production line, delivering the economics of mass-production with digital printing agility

The Velox IDS 250 direct-to-shape digital decorator delivers superior decoration quality and capabilities at high-volume production levels that outstrip both analog printing solutions and the alternative of printing and applying labels. At the same time, it allows a more efficient and flexible production process, with a low TCO.

Replaces analog decorators

Matches or exceeds the capabilities and benefits of analog direct-to-shape and analog/digital label-based solutions

Delivers superior quality for any decoration profile

Produces photorealistic image quality (up to 1200 dpi), with an ultra-wide color gamut, accurate color matching, and fine texts

Enables unique decoration enhancements

Superior to any direct or indirect decoration solutions available on the market; uniquely enables 360° printing with no slit or overlap, on-cap and on-weld printing, selective embossing, and gloss/matte varnish

Allows efficient manufacturing of any batch size

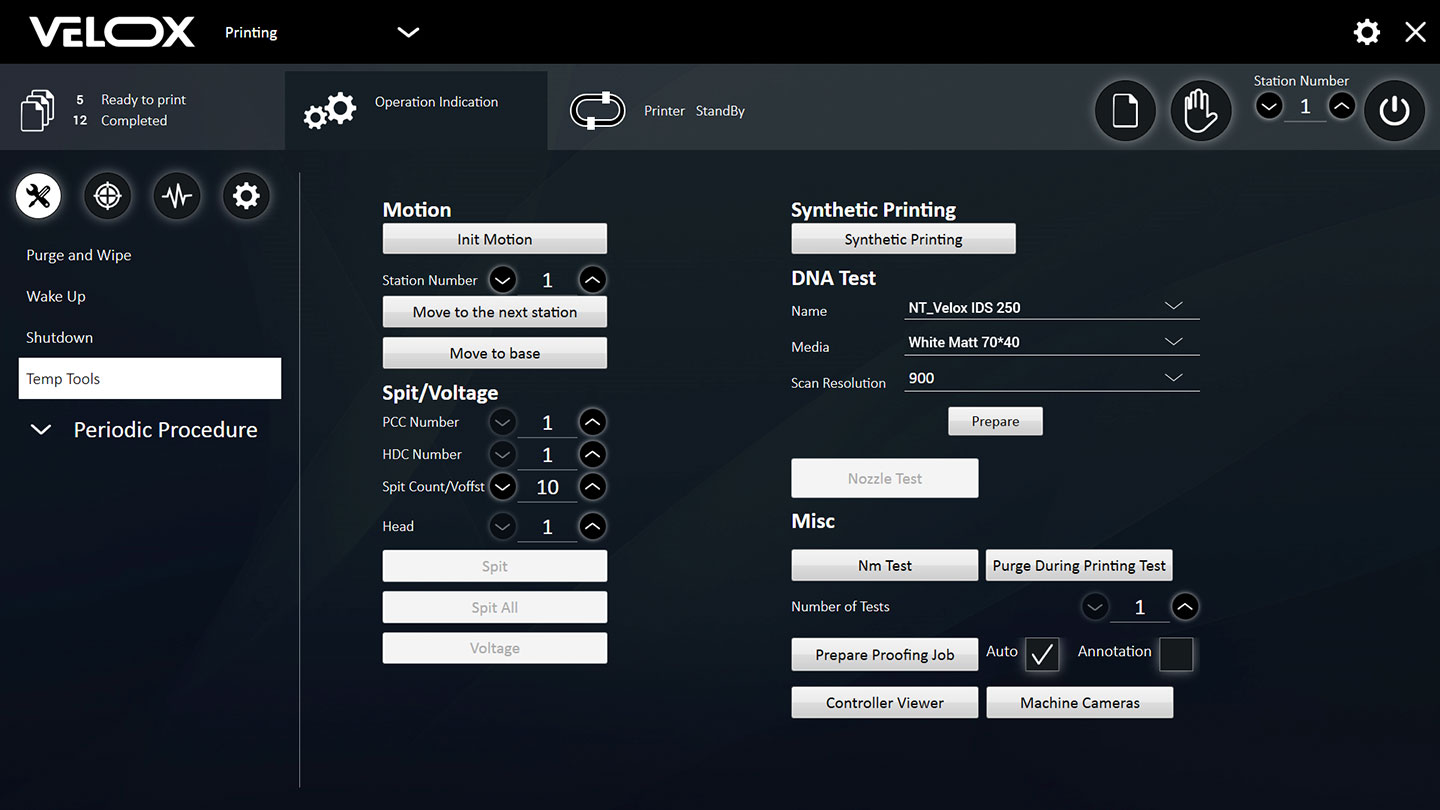

Zero make-ready costs and near-zero setup-time, with no lab preparations or calibration waste, reduce overhead and save operator time

Increases capacity of existing lines

Scalable print speeds that match or exceed production line speeds, along with near-zero setup time, together improve overall line efficiency

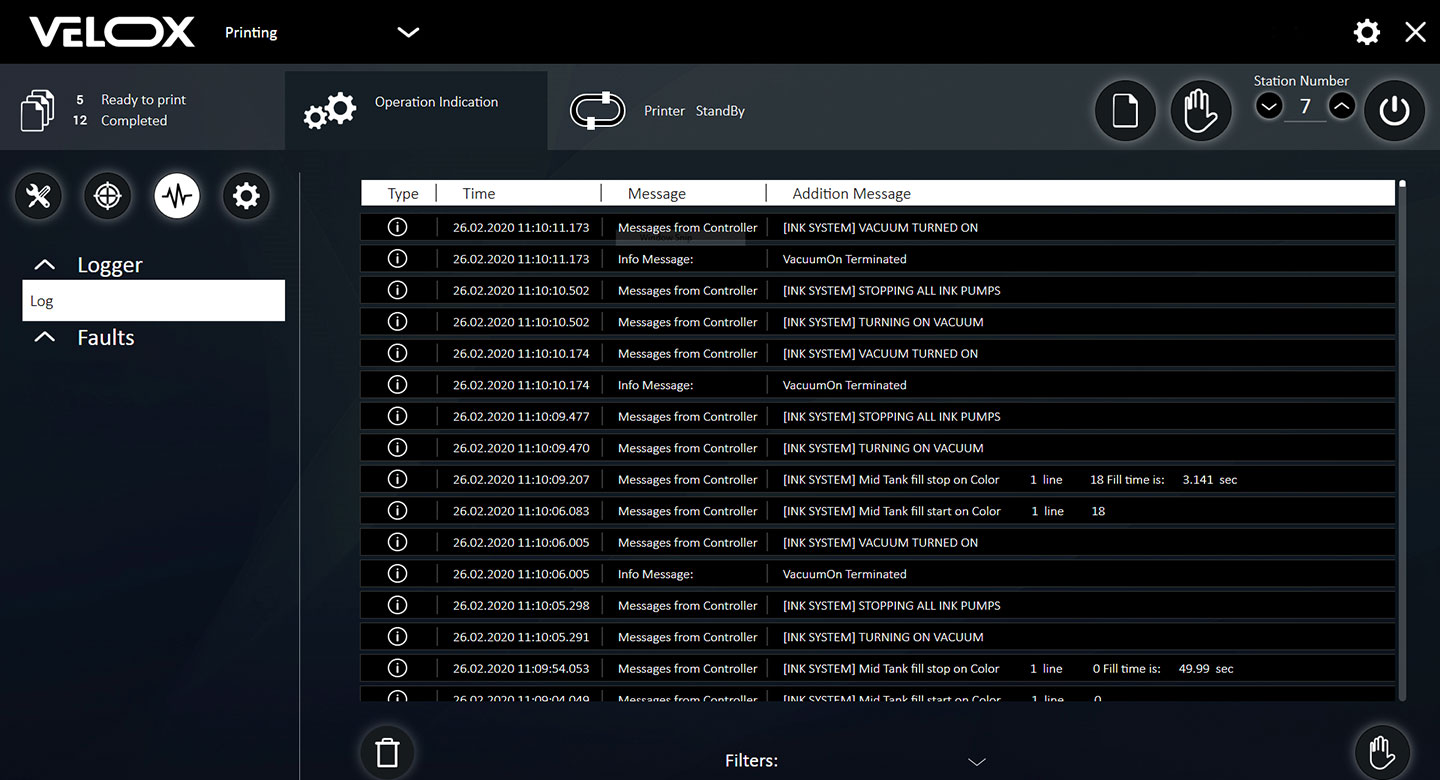

24/7 availability

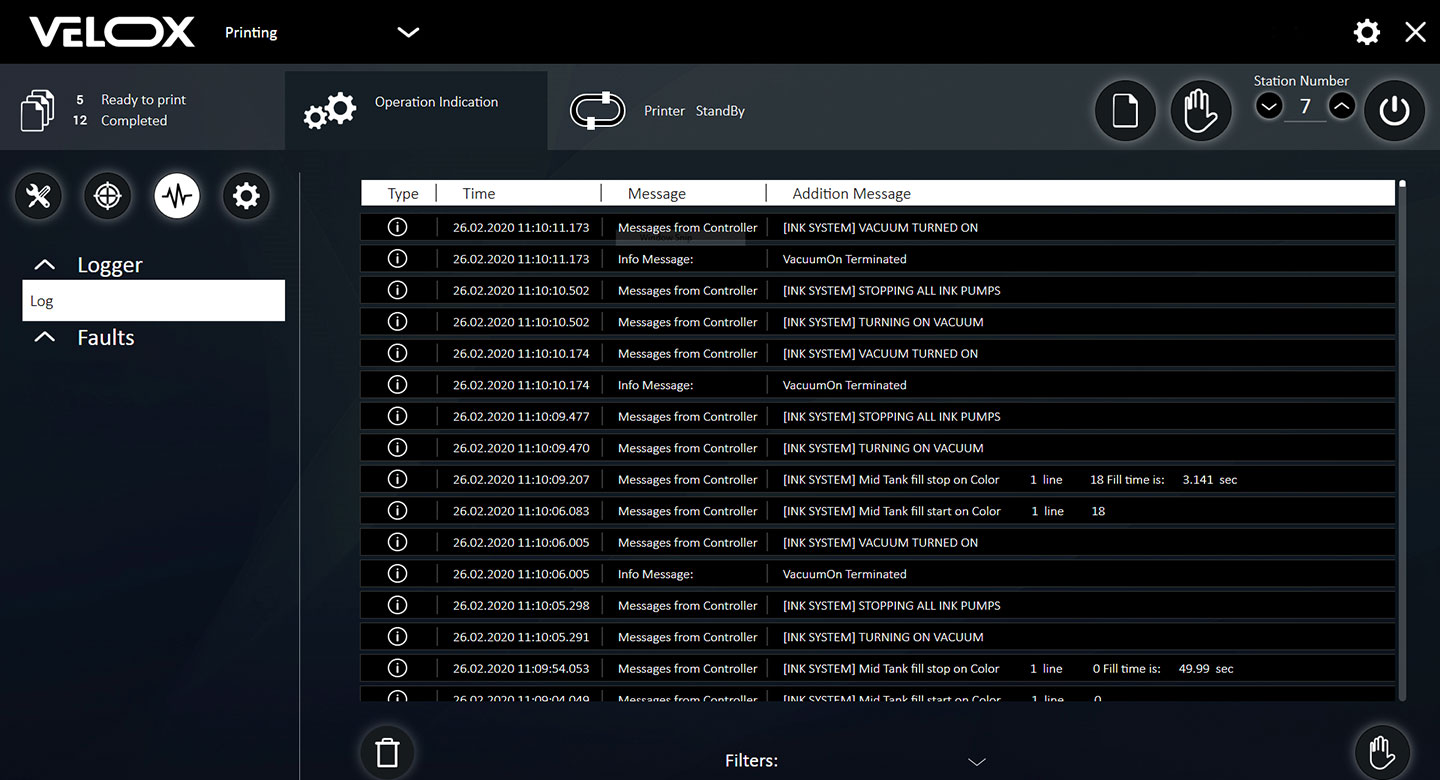

Inherent high reliability is boosted by built-in prevention, self-healing and impact minimization mechanisms

The Velox IDS 250 utilizes a specially formulated family of digital UV inks developed specifically for direct-to-shape decoration. Velox inks ensure superior-quality decoration time after time, offering an ultra-wide color gamut, exceptionally vivid and intense process colors, and advanced enhancement features. With all this, they also deliver the required decoration properties and high ink efficiency.

Our unique system and ink technologies are backed by highly professional technical support. The multiple service plan options offer full spare parts replacement (including print heads), remote and onsite support, training, and more.

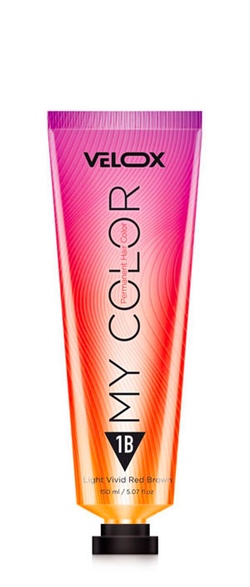

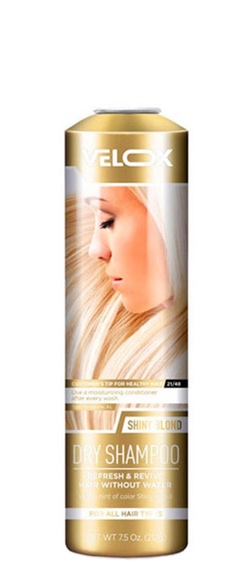

The Velox IDS-PT series is a high-speed, industrial-grade direct-to-shape digital decoration solution for plastic tubes. It enables converters and fillers to gain a strategic leadership position and compelling competitive edge in their markets.

Key Benefits:

Unprecedented decoration quality and capabilities

Print any decoration profile and a unique set of decoration enhancements.

Full production speed

Decorate in high quality at a speed of up to 250 containers per minute regardless of container size.

Low total cost of ownership (TCO)

Combination of high production speed and high ink efficiency makes the Velox IDS-PT series premier decoration solution for the production line, delivering the mass-production economics with digital printing agility.

Built-in sustainability

Eco-friendly solutions that reduce environmental footprint across the entire decoration process and beyond.

The Velox IDS-PT series direct-to-shape digital decorators deliver superior decoration quality and capabilities at high-volume production levels that outstrip both analog printing solutions and the alternative of printing and applying labels. At the same time, they allow a more efficient and flexible production process, with a low total cost of ownership and enhanced sustainability.

Replaces analog decorators

Matches or exceeds the capabilities and benefits of analog direct-to-shape and analog/digital label-based solutions

Delivers superior quality for any decoration profile

Produces photorealistic image quality (up to 1200 dpi), with an ultra-wide color gamut, accurate color matching, and fine texts

Enables unique decoration enhancements

Superior to any direct or indirect decoration solutions available on the market; uniquely enables 360° printing with no slit or overlap, on-cap and on-weld printing, selective embossing, and gloss/matte varnish

Allows efficient manufacturing of any batch size

Zero make-ready costs and near-zero setup-time, with no lab preparations or calibration waste, reduce overhead and save operator time

Increases capacity of existing lines

Scalable print speeds that match or exceed production line speeds, along with near-zero setup time, together improve overall line efficiency

24/7 availability

Inherent high reliability is boosted by built-in prevention, self-healing and impact minimization mechanisms

Velox solutions utilize a specially formulated family of digital UV inks developed specifically for direct-to-shape decoration. Velox inks ensure superior-quality decoration time after time, offering an ultra-wide color gamut, exceptionally vivid and intense process colors, and advanced enhancement features. With all this, they also deliver the required decoration properties and high ink efficiency.

Our unique system and ink technologies are backed by highly professional technical support. The multiple service plan options offer full spare parts replacement (including print heads), remote and onsite support, training, and more.

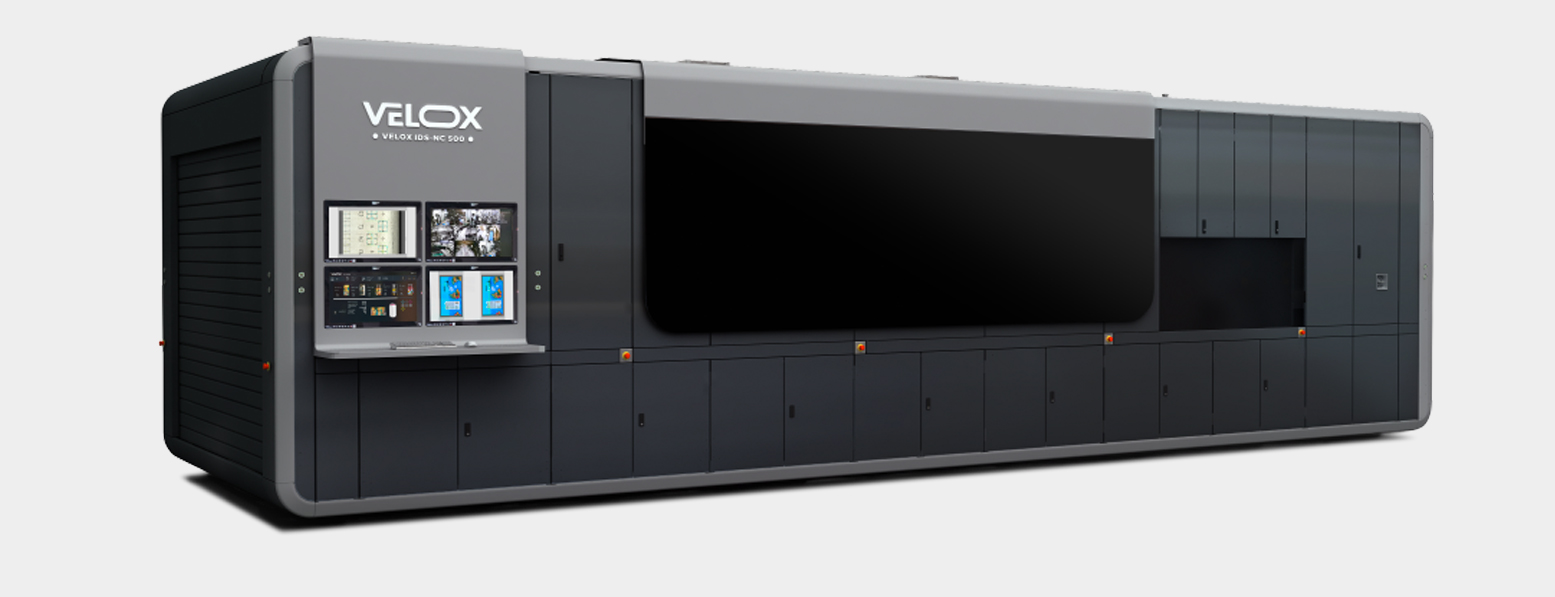

The Velox IDS-NC series is an advanced digital decoration solution for necked beverage cans, offering a replacement for mass-production shrink sleeves and labels. It delivers high-quality printing with utmost operational agility, while maintaining a low total cost of ownership and enhancing sustainability.

Key Benefits:

Unprecedented decoration quality and capabilities

Prints any decoration profile and a unique set of decoration enhancements.

Full production speed

Decorates in high quality at a speed of up to 500 containers per minute.

Low total cost of ownership (TCO)

Removes sleeve and label material and application costs and delivers high production capacity thanks to high system speed, minimized setup and time saving on sleeve/label handling and application. All this together makes the Velox IDS-NC the ideal solution for mass production of necked beverage cans.

Built-in sustainability

Eliminating the need for plastic shrink sleeves and labels, the Velox IDS-NC series offers an eco-friendly solution that reduces environmental footprint across the entire decoration process and beyond.

The Velox IDS-NC series delivers high-quality decoration and unique capabilities at mass production speed – offering an unbeatable alternative to shrink sleeves and labels. In addition, it provides utmost operational agility, a low total cost of ownership and enhanced sustainability.

Delivers superior quality for any decoration profile

Produces photorealistic image quality (up to 900 dpi), with a wide color gamut, accurate color matching, selective opaque white and metallic colors.

Enables unique decoration enhancements

Seamless 360° printing with no slit or overlap, printing on the chime and necked area, selective digital gloss, and matte varnish.

Allows efficient manufacturing of any batch size

Near-zero setup time, extremely high decoration speed, process simplification and automated processes reduce overhead and save operational time.

Cost-efficient replacement of sleeves and labels

High system speed and near-zero setup time while saving on sleeve/label handling, application time and material costs, and allowing decoration on demand and reduced overproduction and inventory.

24/7 availability

Inherent high reliability is boosted by built-in prevention, self-healing and impact minimization mechanisms.

Velox solutions utilize a specially formulated family of digital UV inks developed specifically for direct-to-shape decoration. Velox inks ensure superior-quality decoration time after time, offering a wide color gamut, exceptionally vivid and intense process colors, and advanced enhancement features. With all this, they also deliver the required decoration properties and high ink efficiency.

Our unique system and ink technologies are backed by highly professional technical support. The multiple service plan options offer full spare parts replacement (including print heads), remote and onsite support, training, and more.

The Velox IDS-BC series is an industrial-level, direct-to-shape digital decoration solution for high-volume production of straight wall beverage cans. Delivering significant advantages over offset decoration, it offers can manufacturers a cost-effective and reliable digital decoration solution for small-to-mid-scale runs, marketing campaigns and other new segments.

Key Benefits:

Unprecedented decoration quality and capabilities

Prints any decoration profile and a unique set of decoration enhancements.

Full production speed

Decorates in high quality at a speed of up to 500 containers per minute.

Low total cost of ownership (TCO)

Minimizing decoration processes and removing setup expenditures while providing near-zero setup and maximum machine uptime, the Velox IDS-BC series reduces short-run expenses and delivers a fast return on investment.

Built-in sustainability

An eco-friendly solution that reduces environmental footprint across the entire decoration process and beyond.

The Velox IDS-BC series of high-volume direct-to-shape digital decorators is a robust, eco-friendly solution that delivers unprecedented printing quality, increases operational flexibility and reduces total cost of ownership.

Delivers superior quality for any decoration profile

Produces photorealistic image quality (up to 900 dpi), with a wide color gamut, accurate color matching, selective opaque white, and metallic colors.

Enables unique decoration enhancements

Seamless 360° printing with no slit or overlap, printing on the chime, selective digital gloss, and matte varnish.

Allows efficient manufacturing of any batch size

Zero make-ready costs and near-zero setup-time, with no lab preparations or calibration waste, reduce overhead and save operator time.

Cost-efficient replacement of small-to-mid-scale offset decoration runs

Scalable print speeds along with high-volume production speeds and near-zero setup time to cost efficient decoration for marketing campaigns, mid-size drink brands and focus groups.

24/7 availability

Inherent high reliability is boosted by built-in prevention, self-healing and impact minimization mechanisms.

Velox solutions utilize a specially formulated family of digital UV inks developed specifically for direct-to-shape decoration. Velox inks ensure superior-quality decoration time after time, offering a wide color gamut, exceptionally vivid and intense process colors, and advanced enhancement features. With all this, they also deliver the required decoration properties and high ink efficiency.

Our unique system and ink technologies are backed by highly professional technical support. The multiple service plan options offer full spare parts replacement (including print heads), remote and onsite support, training, and more.

The Velox IDS-AC and Velox IDS-SC series are high-speed, industrial-grade direct-to-shape digital decoration solutions for straight-wall and shaped aerosol cans. They enable converters and fillers to gain a strategic leadership position and compelling competitive edge in their markets.

Key Benefits:

Unprecedented decoration quality and capabilities

Print any decoration profile and a unique set of decoration enhancements.

Full production speed

Decorate in high quality at a speed of up to 250/500 containers per minute regardless of container size.

Low total cost of ownership (TCO)

Combination of high production speed and high ink efficiency makes the Velox IDS-AC and Velox IDS-SC series premier decoration solutions for the production line, delivering the mass-production economics with digital printing agility.

Built-in sustainability

Eco-friendly solutions that reduce environmental footprint across the entire decoration process and beyond.

The Velox IDS-AC and Velox IDS-SC series direct-to-shape digital decorators deliver superior decoration quality and capabilities at high-volume production levels that outstrip both analog printing solutions and the alternative of printing and applying labels. At the same time, they allow a more efficient and flexible production process, with a low total cost of ownership and enhanced sustainability.

Delivers superior quality for any decoration profile

Produces photorealistic image quality (up to 1200 dpi), with an ultra-wide color gamut, accurate color matching, and fine texts

Enables unique decoration enhancements

Superior to any direct or indirect decoration solutions available on the market; uniquely enables 360° printing with no slit or overlap, on-cap and on-weld printing, selective embossing, and gloss/matte varnish

Allows efficient manufacturing of any batch size

Zero make-ready costs and near-zero setup-time, with no lab preparations or calibration waste, reduce overhead and save operator time

Increases capacity of existing lines

Scalable print speeds that match or exceed production line speeds, along with near-zero setup time, together improve overall line efficiency

24/7 availability

Inherent high reliability is boosted by built-in prevention, self-healing and impact minimization mechanisms

Velox solutions utilize a specially formulated family of digital UV inks developed specifically for direct-to-shape decoration. Velox inks ensure superior-quality decoration time after time, offering an ultra-wide color gamut, exceptionally vivid and intense process colors, and advanced enhancement features. With all this, they also deliver the required decoration properties and high ink efficiency.

Our unique system and ink technologies are backed by highly professional technical support. The multiple service plan options offer full spare parts replacement (including print heads), remote and onsite support, training, and more.